In connection with purchasing a vertical storage system, more often than not, the question of integration towards the vertical storage lift or vertical carousel will come up – but what does integration really mean? In this guide, we try to clarify the most common questions. We hope to give you a better understanding ahead of a potential integration between your system and the vertical storage system.

Connecting the vertical storage systems

To “connect” the vertical storage system is the phrase generally used in connection with creating an integration from your ERP or WMS to your vertical storage lifts or vertical carousels. The integration will enable you to automatically transfer locations, items, and orders from your ERP/WMS and thereby get streamlined logistics with few manual operations.

In detail, which systems are involved?

As mentioned above, an integration implies connecting your current systems with the vertical storage system, but in detail, which systems are normally involved? The answer to that question is generally described by one of the two scenarios below:

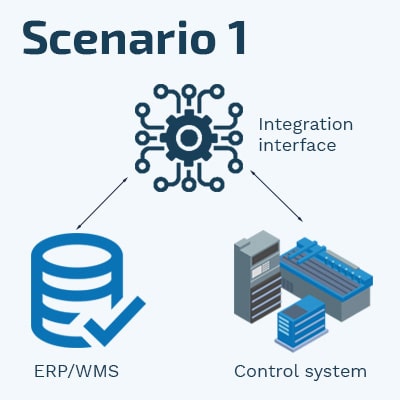

1. Integration between your ERP/WMS and the vertical storage systems integration interface

If you have concluded that you are going to use your ERP/WMS to control the vertical storage system, this is the type of integration you are likely to do.

In this case, all master data such as locations, items, and customer orders will continue to be created and administered in your ERP/WMS. Likewise, the end-user will continue using your ERP/WMS to conduct warehouse operations such as picking, put away, and stock take.

The integration will be made between your ERP/WMS and an integration interface that the vendor of the vertical storage system provides. The integration interface simplifies the communication with the vertical storage systems control system, as a result, the master data from your ERP/WMS will automatically fetch the right tray when a picking order or put away order is to be carried out.

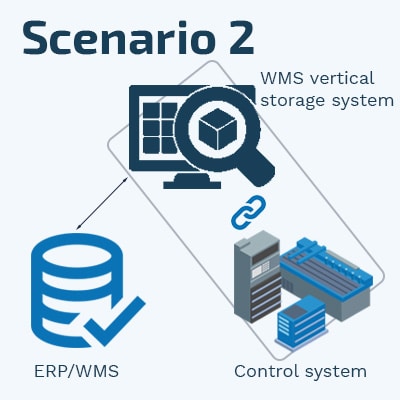

2. Integration between your ERP/WMS and the vertical storage systems’ WMS

If your ERP/WMS lacks the functionality you need to create an efficient warehouse flow, it is likely that you will integrate your ERP/WMS with the vertical storage systems WMS.

In this case, the vertical storage systems WMS will control more of both the data and the logic that is required to use the vertical storage lift or vertical carousel. Master data such as customer orders and items will still be handled in your ERP/WMS, however, data such as locations, and logic to create optimized picking batches will be held in the vertical storage systems WMS. The end-user will work in a user interface provided by the vertical storage systems WMS.